ROD SERVICES

Well Servicing

Well ServicingROD SALES

LOCATIONS

EQUIPMENT

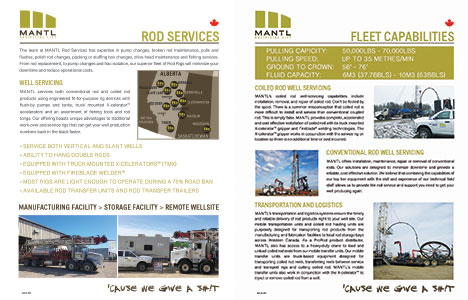

The team at MANTL Rod Services has expertise in pump changes, broken rod maintenance, pulls and flushes, polish rod changes, packing or stuffing box changes, drive head maintenance and fishing services. From rod replacement, to pump changes and frac isolation, our superior fleet of Rod Rigs will minimize your downtime and reduce operational costs.

MORE EXPERIENCE = LESS DOWNTIME

Well Servicing

MANTL services both conventional rod and coiled rod products using engineered fit-for-purpose rig derricks with flush-by pumps and tanks, truck mounted X-celerator™ accelerators andan assortment of fishing tools and rod tongs. Our offering boasts unique advantages to traditional work-over and service rigs that can get your well production numbers back in the black faster.

I COILED ROD WELL SERVICING

II CONVENTIONAL ROD WELL SERVICING

III TRANSPORTATION AND LOGISTICS

I COILED ROD WELL SERVICING

MANTL’s coiled rod well-servicing capabilities include installation, removal, and repair of coiled rod. Don’t be fooled by the spool. There is a common misconception that coiled rod is more difficult to install and service than conventional coupled rod. This is simply false. MANTL provides complete, accelerated and cost effective installation of coiled rod with its truck mounted X-celerator™ and Fireblade® welding technologies. The X-celerator™ works in conjunction with the service rig on location so there is no additional time or cost incurred.

|

II CONVENTIONAL ROD WELL SERVICING

MANTL offers installation, maintenance, repair or removal of conventional rods. Our solutions are designed to minimize downtime and provide a reliable, cost effective solution. We believe that combining the capabilities of our top tier equipment with the skill and experience of our technical field staff allows us to provide the rod service and support you need to get your well producing again.

|

III TRANSPORTATION AND LOGISTICS

MANTL’s transportation and logistics systems ensure the timely and reliable delivery of rod products right to your well site. Our mobile transportation units and coiled rod hauling units are purposely designed for transporting rod products from the manufacturing and fabrication facilities to local rod storage bays across Western Canada. As a ProRod product distributor, MANTL also has access to a heavy-duty crane to load and unload coiled rod reels from our mobile transfer units. Our mobile transfer units are truck-based equipment designed for transporting coiled rod reels, transferring reels between service and transport rigs and cutting coiled rod. MANTL’s mobile transfer units also work in conjunction with the X-celerator™ to inject or remove coiled rod from a well.